Objective

Provide a charging point for an electric vehicle or two

Goals

Prepare premises electrical service and electrical distribution to power new EVSE charging point and future addition of cold-climate heat pump heating and cooling and heat-pump water heater. Ensure distribution is up to code.

Background

The current distribution panel shown here is an example of design on the job. Panel installer overlooked the constraints imposed by the field and picked a too-tall panel. Yes, you can see daylight there.

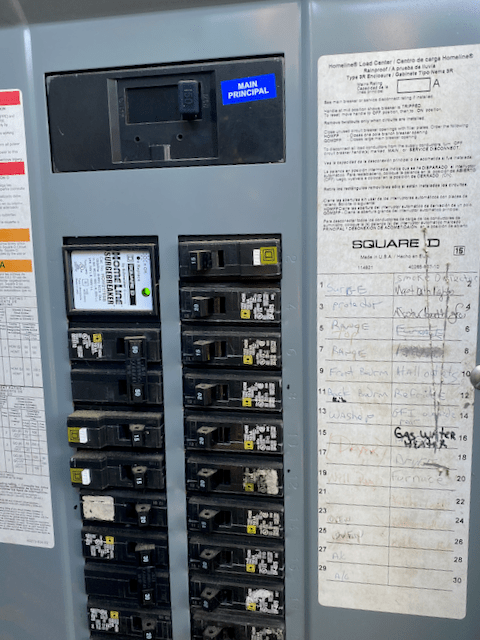

The SQUARE-D HOMELINE 30 slot panel shown in the photos was installed in 2005-2006 in advance of an HVAC upgrade. The original work wiring and the meter conduit constrain the location of this panel. Because of its height, the legacy panel comes over the soldier course. In this photo, the upper edge of the final horizontal course is about 28 inches above the bottom of the meter panel. The too-tall panel is tipped allowing potential for water and critter entry. Original construction field wiring enters the panel through the lowest row of back plate knock outs.

This next image shows the conduit added to run the kitchen circuits back to the panel. This is old growth brick from 1955 and is quite dense and difficult to drill. Much gnashing of teeth drilling the three new risers. The earthing star connector block appears in this photo. The larger conduit houses the 240V circuits for the cook top, oven, and dryer.

Since then, the bathrooms have been remodeled, a small addition added, and the kitchen remodeled with kitchen circuits brought up to code.

The kitchen remodel consumed most of the spare in the panel. There is presently one 2 pole position remaining in the panel. All breakers in the current panel are in good condition.

The original panel was located in the MBR closet behind the current panel. The original owner installed a breaker panel at the current location prior to the current owner taking possession, possibly when the first air-conditioning was installed.

The original wiring was home run to the MBR fuse panel, since removed. Original wiring was rerouted to the current location and new circuits run from the current location

Requested Scope of Work

- Evaluate the existing service. The panel has a 150 Amp main breaker. Does our service connection allow upgrade to a 200 Amp main breaker? Owner is concerned about the HVAC and the car charger interacting to trip the breaker. Current HVAC has Lennox Elite 16 capacitor start compressor.

- Evaluate 240V run to the HVAC compressor for possible reuse with new equipment. I expect Mitsubishi 48,000 BTU/Hour compressor units in the future equipment, likely 2 to cover heating load. Current machine is 24,000 BUT/Hr and breaks even at 45F. This machine is capacitor start, capacitor run. Future machines will have soft-starting variable speed drives.

- Install a new panel providing a 2 pole position for the EVSE and 2 additional 2 pole positions for future HVAC compressors. Cable and breakers will be added when the new machines are installed.

- Provide 5 spare 2 pole positions for future expansion. That includes the two bespoke positions mentioned above.

- Install whole house surge suppression as needed to protect all service circuits.

- Install AFCI breakers as required by code. There are currently AFCI breakers in those positions.

- Consider providing combination AFCI/GFCI breakers for the two circuits called East and West. These have the 2-wire outlets and original lighting on them. These positions have only over-current and AFCI protection in the legacy installation.

- Run cable (40 amp) and install an outlet (or directly connect if code requires) for installation of an EVSE charge point when it arrives. Desirable brands of EVSE are on back-order. EVSE will be limited to 32 Amps.

- Provide printed labels for all circuits with particular attention to the following: air handler, refrigerator, HVAC compressor, cook top, oven, Renai water heater, washer, dryer, dishwasher, disposer, east lighting, west lighting, bathrooms and smoke detectors, lounge lighting, kitchen service circuits.

- Review grounding grid for code compliance. Ensure TV Mast, cable DEMARK, and telephone DEMARK, etc are grounded properly to electrical ground. – Ensure that current earthing points are up to code. Make any corrections needed for code compliance. Review wire gages and replace any sub-standard grounding wire.

- Arrange for permits and inspections as required by the City of Norfolk. Quoted price to include permit and inspection fees.

- All work shall pass City of Norfolk inspection.

- Provide panels, breakers, and wiring devices as needed. All panels and devices shall be NEC approved designs.

- Panels to be outdoor-rated and positioned mandated by electrical and building codes.

- Current panel interferes with the soldier course at the top of the brickwork. Panels should be located below the soldier course.

- All work shall comply with the NEC currently in effect in the City of Norfolk Virginia.

- All wiring devices used shall be products approved by the NEC in effect.

Anticipated future work

The owner anticipates the following future work.

- Installation of undercroft dehumidifiers as humidity is 70% in the undercroft.

- Installation of replacement HVAC in the future with transition to all-electric HVAC using cold climate VRF heat pumps and ductless design.

- Possible replacement of the gas water heater by an heat-pump water heater. This may be an additional load on the HVAC heat pumps. Mitsubishi makes air to water heat exchanges for domestic water heating.

These projects will likely require new circuits and the panels shall have sufficient spares (minimum of 2 2-pole positions and 1 1-pole position.) The owner would prefer 10 spare positions.

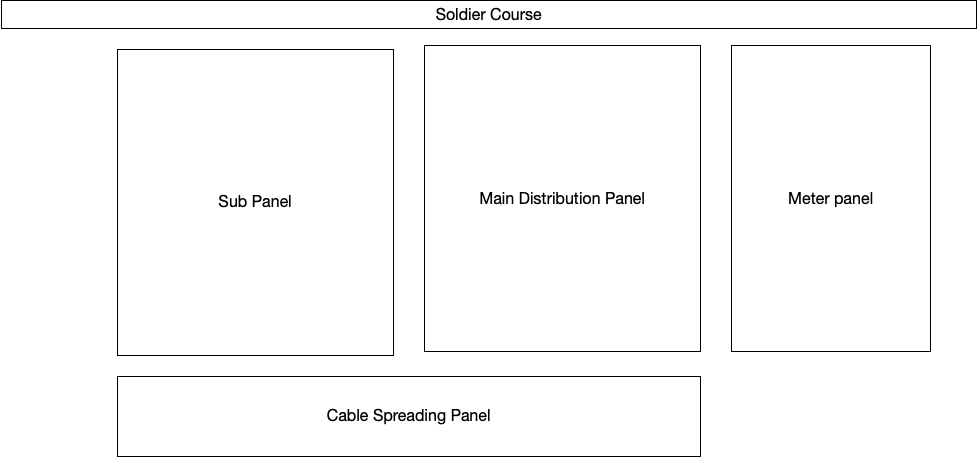

Conceptual Design

Figure 1 shows a notional arrangement intended to resolve the limitations imposed by the original work panel location. This design recognizes that the bottom of the service panel is cramped as the mains are routed through this area.

This design introduces a cable spreading enclosure that can be used to extend existing field wiring into the new panels in a manner that permits orderly cable dress inside the new panels. All of the original work enters the legacy panel through the rear. The new work from the kitchen remodel enters the legacy panel through risers. Use of a cable spreading enclosure is not a requirement of this project provided work can be kept neat and breaker connections dressed in a professional manner.

Owner preference

- The owner has no preference of panel suppliers. Eaton (CH), Schneider Square-D, and Seimens (formerly Westinghouse?) are acceptable brands.

- The owner would prefer snap onto neutral breakers to reduce the use of pig tails in the panel. Compact electronic breaker styles are preferred.

- The owner had the pleasure of purchasing the last Square-D Style SO breakers in Hartford to forestall a panel replacement. He’d prefer not to repeat that experience.

- The owner would prefer that the provided panels rest flat to the brick and not overlap the solder course as shown in the photos.

- The owner realizes that the panel switch will require replacement of Square-D HomeLine breakers in the current panel.

- The owner realizes that use of a sub-panel has the potential to add $200-$300 to job cost.

Photos

Mast to Meter

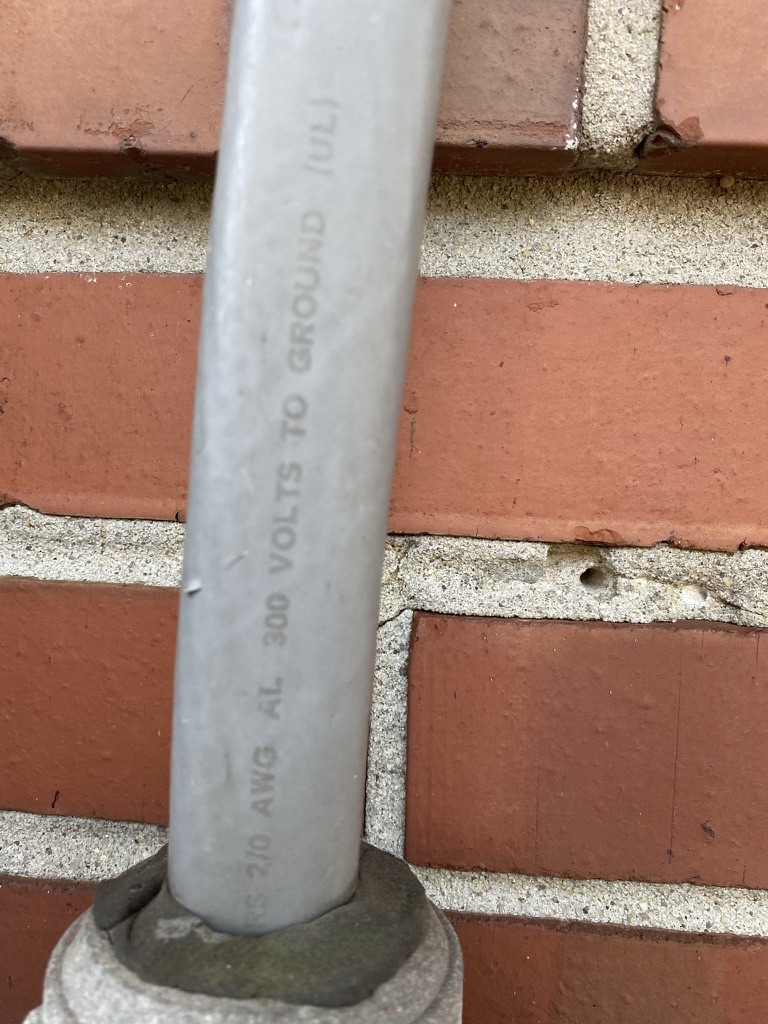

The bottom corner of the soldier course appears under the UL label on the mast feeder cable.

Meter box

The bottom of the meter box is 28.5 inches below the soldier course lower edge. This feature constrains panel height.

Main Breaker

EVSE Location

This location ensures that the charging cable can reach a vehicle parked in the carport and a second parked in the drive. This might be most convenient for future owners.

This location is convenient to the back of a vehicle reversed in to the carport. Reaching a second vehicle reversed into the drive may be problematic.

You must be logged in to post a comment.