Many homeowners are making the move to full-range heat pump residential heating. A full-range heat pump is less expensive than a heat pump plus a gas furnace. A heat pump by itself provides reliable, quiet, comfortable heat. But there are some things to remember. In this post, I’ll review the first winter of full-range heat pump heating.

Revisions

- 2026-01-28 Original

References

The Project

I’ve been living at Dismal Manor for about 20 years. When I first bought the manor, I replaced the windows, reroofed, resided, and updated the heating to a dual fuel heat pump system that replaced the legacy air-conditioner and furnace. Dual fuel is the industry’s term of art for a heat pump paired with a gas furnace for backup heat. This equipment has served well for 20 years but was obsolete (refrigerant changed) and just met building code (SEER-16). The legacy heat pump could heat the building down to 40F outdoor temperature. At that point, the thermostat switched off the heat pump and switched on the gas furnace.

In 2025 Fall, I contracted with a local HVAC service company to replace the 2006 equipment with a modern machine capable of heating Dismal Manor without a backup furnace. This machine was installed in late September and has served well so far. But there has been some learning needed.

HVAC Design Basis

The Energy Star guide [2] lists design basis temperaturs for cooling (95F) and heating (22F) for Norfok City. The outdoor temperature is between these limits 99% of the time and outside them 1% of the time. Surprise, 1% is about 1/2 week, say 4 days. A well designed heat pump system will easily exceed the cooling requirement and just meet the heating requirement. The idea is to correctly size the system so that it runs continuously during the coldest hour.

Inverter Driven Systems

Usign inverter drive, modern systems adapt their capacity to the load by operating at a reduced speed on milder days. The Bosch does this. It is not apparent from the thermostat’s calls for heat (stage 1, 2, or aux). Rather, the Bosch system (others may use different strategies) controls speed to achieve planned thermodynamic conditions in the indoor coil. Compressor speed, fan speed, and indoor blower speed are adjusted using operating maps.

Fall Operation

October and November turned out to be months of low demand. That’s typical of fall. Heating season begins in December. One thing I learned is that the building sheds enough internal heat to maintain indoor temperature when outdoor temperature was above 50F or 10C. This was a surprise.

The second thing I learned was that Energy Star and Ecobee setting recommendations were made for a traditional furnace or boiler and not for heat pump heating An earlier post talks about this at length.

Winter Operation

Before it got really cold, I tinkered around with setting schemes. I slowly lowered the temperature from what I was accustomed to to 68F or 20 C which is the indoor winter recommendation here and abroad. I found this to be a comfortable temperature with the new equipment which actually included a working humidifier properly installed and controlled. Just before winter roared in, I had settled on 68F with no set backs for night and away. Heat pumps like to be left alone as a properly specified system is closely matched to th ebuilding.

Then It Snowed

Snow storms here often feature temperature near freezing with high relative humidity. The machine iced up.

Heat pumps are refrigeration machines that move heat from outdoors to indoors in heating mode and from indoors to outdoors in cooling mode. They are always moving heat “uphill” from cooler to warmer. This takes energy input and compression and expansion of a working fluid (refrigerant).

In winter, there is still heat in the air and moisture in the air. Much of the time, the outside coil surface temperature is below the dew point and below freezing. Ice forms on the coils of this heat excanger as shown above.

Heat pumps work in winter because there is always heat in the air. Thermodynamical systems works on “absolute” temperature. Heat is the manifestation of molecules in motion and there is always heat in the air no matter how cold.

For a heat pump to work, the air temperature has to be warmer than the boiling point of the refrigerant in the outdoor coil. The refrigerant evaporates and expands in the outdoor coil absorbing heat from the air. The refrigerant is pumped indoors where it condenses in the indoor coil releasing its heat to the air flowing rough the coil.

A reversing valve determines the direction of refrigerant flow. When energized, it swaps the roles of the indoor and outdoor coils to allow th emachine to heat the indoors. Normally, the coils are lined up to cool the indoors.

Icing Happens …

Icing is refrigeration’s version of stuff happens. When the surface of the outdoor coil is cooler than the dew point, atmospheric water vapor condenses on the coil. This is ok normally as the coil captures the latent heat of condensation for transfer inside. When the coil surface is also colder than the freezing point, the water freezes giving up yet more heat to the coil. But it also ices the coil blocking air flow thrug the coil. Icing reduces the capacity of the machine. The machine shown is rated at 10 KW (3 tons). The whole rest of the world uses KW for heat energy measure. We’re stills talk in BTUs and tons of ice melted per hour.

Defrosting Happens

Anyway, ice is bad and must be removed. Every so often, the machine’s brain calls for a defrosting cycle. It shifts the reversing valve and stops the outdoor fan so the compressor can circulate refrigerant thrugh the outdoor coil. Pump heat melts the ice. You’ll see a vapor cloud flowing away from the outdoor unit during defrost.With luck, the ice will melt and fall free. That’s why the outdoor unit is mounted on risers, to allow the ice to clear during defrost.

Behavior changes during icing

The Bosch IDS family changes its behavior during icing. The indoor and outdoor units talk to each other. When the outdoor sensors detect low air temperature and high relative humidity, the unit operates to limit indoor coil temperature. In practice, my machine keeps 20 C indoor temperature. Resistance is futile. Setting the thermostat higher makes the greedy 5 KW aux heaters run more or run continually.

The heat pump has a cop of 2 at 10F. It will deliver twice the electrical input to the indoor coil at 10 F. The aux heat always delivers its electrical input, ie it has a COP of 1. Aux heat on is bad. So I waoked the set point by degrees from 72F to 68F and found that I’m comfortable at 68F with an extra layer or two..

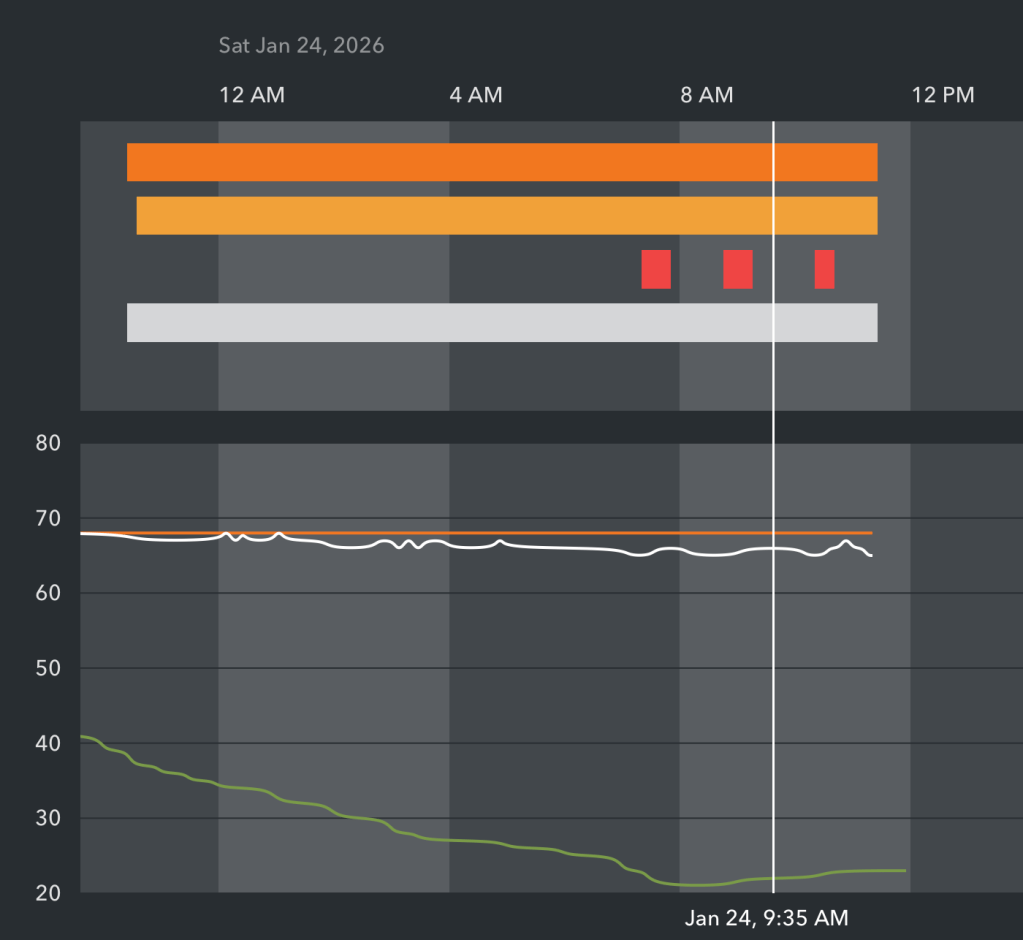

The system keeps 66 to 68 F down to 20F outdoors using the aux heat during the coldest hours of the night.

This image captured from our Ecobee thermostat shows stages one and 2 heating running with the aux heat cycling. The amount the process is below the set point determines staging — one, two, or aux heating. The error thresholds are set in the thermostat’s configuration data. My contractor set these. I’m guessing they ar 1, 2, and 3 degrees F (traditional). Raising the setpoint 3F above the current indoor temperature will activate the Aux heat.

You must be logged in to post a comment.