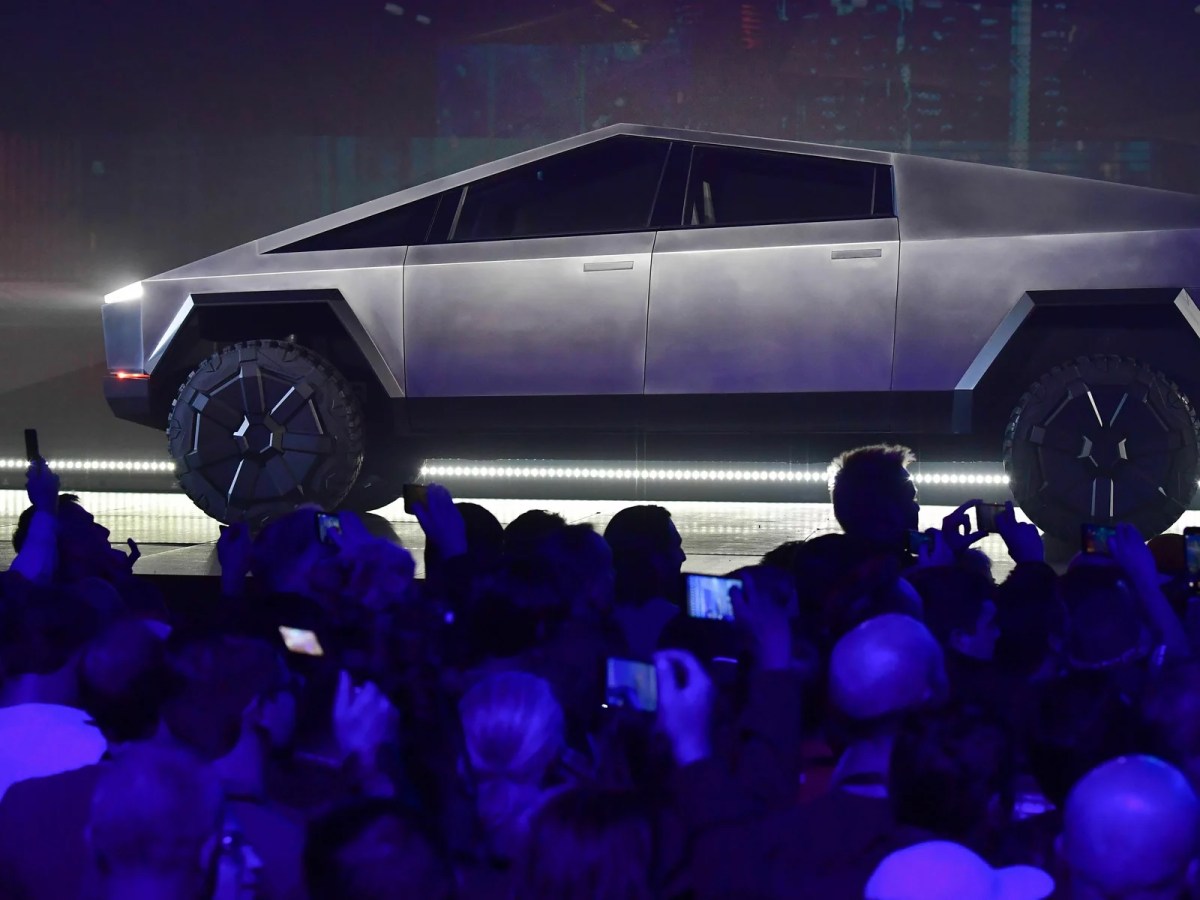

Elon Musk’s young son asked Dad why the future did not look like the future, well the young boy’s notion of the future. Dad went to work to challenge the Tesla product designers and product engineers to make a truck that looked like it was the future and not another me-too pick ’em up. They did, the 2024 CyberTruck.

In this post, I’ll pull together information from several content creators granted extended driving access to the 2034 CyberTruck to look beneath the skins at the way Tesla is changing the automobile.

Revisions

- 2023-12-04 Original

References

This article’s references are YouTube content creator interviews or production covering first drives of the 2024 CyberTruck. Additionally, Sandy Munro comments on several engineering advances.

Tesla allowed each of the presenters extended access to the CyberTruck to drive for the purpose of reporting initial impressions. These presenters and the Delivery Day owners are the only people not Tesla employees or friends of Elon Musk to have driven a CyberTruck. They are skilled automotive reviewers and presenters who came away favorably impressed.

- CyberTruck Curmudgeon Show Commentary

- CyberTruck First Drive Video

- Sandy Munro CyberTruck Impressions

- TopGear UK Magazine CyberTruck Impressions

- Marques Brownlee (MKBHD) Drives the CyberTruck

- CyberTruck Final Assembly Line Tour

- MotorTrend and AutoLine talk CyberTruck line cost

- Tesla Website CyberTruck page

Just what is a CyberTruck?

Ostensibly, CyberTruck is a stylized pickup truck. It has load and towing capacity similar to other contemporary “half-ton trucks” but it is fully electric and has a novel appearance and construction. It raises several questions.

- Can it truck?

- Who is it for?

- Why is it important?

The answers to these questions will emerge over the next year as Tesla delivers CyberTrucks, owners drive them, and owners tell their stories. And as the automotive press reviews the CyberTruck if they have the chance.

Sandy Munro and Marques Brownlee both have CyberTruck reservations. Sandy is after 2, one for his personal use and one for Munro Associates staff to tear-down and analyze. Munro Associates will produce one of its costing and analysis reports for this vehicle.

Can CyberTruck Truck?

Up to now, nobody has used the CyberTruck as a work truck to schlep, say, landscape mulch or stone, serve as a farm or construction machinery tender, or work as a tradesman’s truck hauling small amounts of construction materials and tools.

Who is CyberTruck For?

Outdoorsman and automotive engineer Sandy Munro believes outdoorsmen will be CyberTruck’s primary audience. Sandy is a deer hunter, trail rider, and off-road truck adventure enthusiast. He believes the truck is ideally designed for these pursuits because its stainless steel clad is trail-rash resistant (it won’t scratch or dent rubbing a sapling or obstacle), it is single track unimproved road crawler, and the bed easily carries off-road motorcycles and 4-wheelers. It has adequate range and ground clearance for use as a wilderness access vehicle. It has adequate towing capacity to pull a travel trailer.

Sandy comments that the Ford F-150 Lightning is better equipped to be a contractor’s office and work truck. That’s what Ford does. And Sandy’s wife drives an Rivian R1T that they own. Sandy feels that the Rivian R1T is the better family truck. Sandy drives a Tesla Model 3 and a Ford F-150 Lightning that are Munro Associates vehicles. The Model 3 is his daily commuter car.

Reviewer Common Impressions

CyberTruck driving dynamics has impressed everyone who has driven it. It is quick. It is stable. It is well-behaved up to the limit. Jason raced his truck against a kart on a kart track. The kart closed in the chicanes but the truck walked away on the longer straights. Occasionally, Jason lifted an inside wheel but the CyberTruck never broke loose.

Everybody has found the cabin quiet and comfortable with good seats and climate control. And the ride civilized, something pickup trucks are not known for.

Oh, and it is wicked fast, 2.6 seconds to 60 MPH and will run 11 second quarter miles down to 30% charge remaining. Over and over. No modes. No preconditioning. Just put it in Beast Mode to load the fast maps and mat it. Drive back to the start and do it again.

Why is CyberTruck Important?

Tesla is full of engineers who heard “It will cost too much” one too many times with their former employers. When Elon Musk challenged them to make a future truck rather than a me-too truck. They realized Elon wanted a truck that was the future under the skin in addition to its visible presentation. While cost was an object, “it’ll cost too much” was not an acceptable reason not to explore emerging technology. The objective was to minimize the vehicle’s assembled cost by optimizing across subsystems and not just the cost of the bits and pieces.

- They changed the truck’s skin.

- They changed the structure under the truck’s skin.

- They changed the electrical architecture.

- They changed the control architecture.

- They eliminated the paint shop

- They simplified the body shop

- And they dared to mix in some rocket science.

To make 50,000 per year, Sandy Munro estimates that the body shop line that assembles CyberTruck will cost about $30 million for the panel cutting and forming machines and that the $1 billion paint shop with its environmental challenges is eliminated.

Robots Do Much of the Work

During the Delivery Day event, the CyberTruck prototype line was running in “demo-mode”. Each station on the final assembly line was doing a pick and place operation to demonstrate the assembly action occurring in that cell. The line was static and nothing was added to the body being built up in that cell.

Only final assembly was on display but static exhibits talked about the body shop, giga-castings, and build up of the “body in white” that is the truck’s skeleton from the castings and stampings. The finish panels are stamped from 300 series stainless steel made to a Tesla-developed recipe that was bendable and stain resistant.

These panels are attached to the frame with adhesive to be the exterior “A-surface” or customer visible finished surface. An inner door frame defined the door’s perimeter and gave some strength but much of the impact resistance and penetration resistance came from the hard fricking steel sheathing.

Most of the fiddly hand work happens on spur lines to build the front and rear cradles, the thermal management system on the front strut tower cross-brace, and the instrument panel assembly. The carpet, seats, and other center cabin bits mount atop the battery pack and are rigged up into the structure formed by the roof and door rings.

Much of the hand assembly uses spring clips rather than threaded “unfasteners”. Assembly is simplified and no Locktite is used. For example, the wiring harness clips to cableways built into the door rings or onto the front and rear giga-castings.

Impact Resistant Materials

That HFS sheathing is important because it allows the truck to shrug off rubs against trees and be resistant to hail damage. Leave an F-150 out in a severe thunderstorm dropping “gorilla hail” and it will need most of its panels replaced. A CyberTruck will be undamaged and the glass will be undamaged. The window glass was qualified for class 4 hail resistance.

On a 2000 road trip, I saw an F-150 that wasn’t put under canopy as a storm was approaching. Owner was late to supper so left it out. The storm dropped a load of hail covering the truck with marble-sized dents. The glass had been repaired but not the hood, roof, fenders, and other horizontal surfaces exposed to the hail.

Advanced Electrical System

CyberTruck has an 800 volt drive power architecture. This halves the wire sizes needed to deliver power and in the motors. Motor weight is reduced. Fewer power transistors are needed in the inverters.

CyberTruck has a 48 volt auxiliary power architecture. This reduces auxiliary component current for the steering motors and ventilation motors by a factor of 4. Parasitic loses in this wiring is reduced by a factor of 16 increasing the truck’s efficiency.

Rocket Science, Drive By Wire

Ships and aircraft have been fly by wire for decades. Space craft are almost entirely computer controlled. In automobiles, various actuators are now control by wire but brakes and steering are just now becoming fly by wire.

In CyberTruck, there is no physical connection between the steering wheel and the steering rack. Electrical servo motors position the rack. The column spearing hazard is eliminated. The steering can be variable ratio and variable assist. The driver assistance can intervene more easily. Oh, and right hand drive is much easier. Only the instrument panel is mirror imaged. The forward compartment is unaffected.

Power and Control Share Wiring?

In passing, Sandy mentioned that technology had been developed to multiplex “command over power” to the various actuators. A command over power capable actuator would require 1 connection rather than 3, the power wire and the command twisted pair. Multiplexing in this manner greatly simplifies the wiring in, say, a door. A typical door wiring harness is thumb sized making it difficult to wire and route. With 48 volt command over power, the door wiring harness would be a bit of ribbon cable. In this segment, Sandy also mentioned Automotive Ethernet, and switched and routed networks allowing faster communication for ADAS (automatic driver assistance systems).